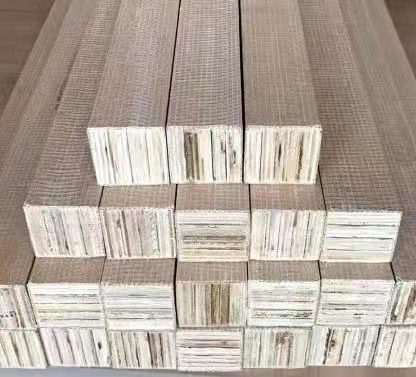

The advantages of 5th generation composite timber

1.Low cost

The production uses waste building formwork or waste wood from the construction site as the main material, and the cost of producing composite wood of the same specification is half that of wood wood.

2. Easy to sell

The main material for the production of composite wood is the waste building formwork or waste wood of the construction site, so we can negotiate with the customer to replace the old composite wood with the old formwork of the construction site, which can easily achieve a win-win situation.

3. Customizable

The composite timber production process is infinitely extended, so the length of the cut can be customized at will.

4, high strength

When producing recycled composite wood, the strength can be arbitrarily matched according to the customer's situation, and the highest value composite wood is more than 3-5 times stronger than that of wooden wood.

5. No deformation

The production of composite wood is made of old formwork strips of about 30cm--100cm, the wood fiber is short and not easy to deform, and the wood produced is all standard size, and the error is within 0.5mm.

6. Good policy

The state advocates that green water and green mountains are gold and silver mountains, advocating the reuse of waste resources, and a composite wood machine is equivalent to cutting down 50 eucalyptus trees every day of composite wood production.

PRODUCT DESCRIPTION

process

1.Waste formwork or wooden sawn into edge strips

2. Glue injection and coating reinforcement mesh, heating curing and setting

3. Cooling and shaping.

Copyright © Shandong Oubiao Machinery Co., Ltd. All Rights Reserved | Sitemap Technical Support: